Chemical hydrogenation reactor

No.: Demei-M-R-002

- Temperature range: 150–420 ℃

- Operating volume: 5–200 m³

- Pressure limit: Maximum design pressure: 22 MPa (220 bar)

- Hydrogen purity: ≥99.9%

- Material: Stainless steel

- Mixing method: Mechanical stirring

- Safety device: Safety valves, rupture discs, pressure/temperature sensors, emergency relief systems

- Remark: Supports crystallization, hydrogenation, and high-pressure screening.

A hydrogenation reactor is a key piece of equipment in the core unit process of "hydrogenation" in the petrochemical, fine chemical, pharmaceutical, and food industries.

-

Petrochemical Industry

- Hydrogenation of olefins and aromatics

- Hydrotreating of diesel and gasoline (desulfurization, denitrification)

-

Edible Oil Industry

- Hydrogenation of vegetable oils to produce margarine and shortening

-

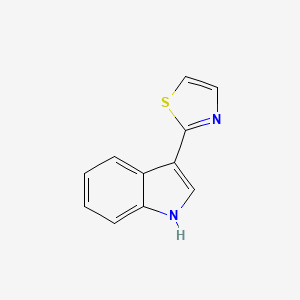

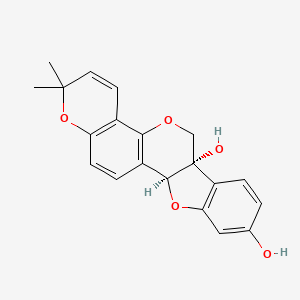

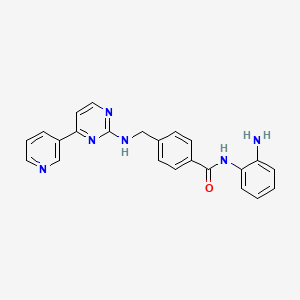

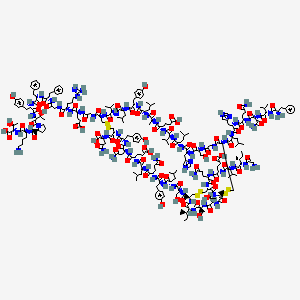

Fine Chemicals and Pharmaceuticals

- Nitrobenzene → Aniline

- Aldehydes/Ketones → Alcohols

- Deprotection, selective reduction, etc.

-

Environmental Protection

- Catalytic hydrogenation degradation of toxic organic substances (such as nitrobenzene compounds) in wastewater

-

New Materials Synthesis

- Synthesis of specialty chemicals, polymer monomers, etc.

The system is sealed using a "steel frame + rubber pad + waterproof fabric" combination, and critical flange openings are sealed with wooden covers or plastic blind plates.

Custom packaging available upon request